Lights-Out Machining using CNC Swiss Machines: How to Prepare and Maximize Efficiency

In the fast-paced world of manufacturing, maximizing machine utilization is crucial for maintaining a competitive edge. Lights-out machining, the process of running CNC machines automatically during off-hours (like overnight or weekends), is an increasingly popular method for improving efficiency. Swiss machines are ideal for this approach due to their precision, versatility, and ability to perform both turning and milling operations in a single setup.

While lights-out machining offers significant benefits such as reduced labor costs and increased production capacity, it requires proper preparation and consideration to ensure success. In this article, we’ll explore how to prepare Swiss machines for lights-out machining, the types of parts that are best suited for this approach, and key programming and tooling tips to ensure smooth and efficient operations.

Read The Top 5 Benefits of Swiss Machining to learn more!

What is Lights-Out Machining Using Swiss Machines?

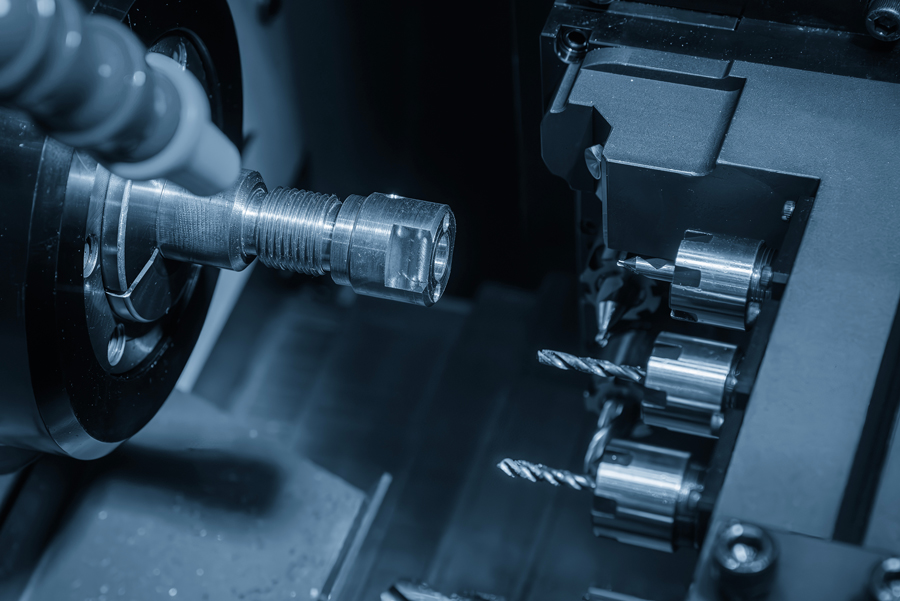

Lights-out machining using Swiss machines refers to running these highly automated machines without the presence of operators, typically during non-business hours. This method allows manufacturers to maximize productivity by running Swiss CNC machines continuously, producing high volumes of small, precise parts while reducing labor costs. Swiss machines are well-suited for lights-out machining due to their ability to perform both turning and milling operations in a single setup, and their capability for high precision and automation. The ability to program and set up Swiss machines to run unattended makes them a great fit for this technique.

Types of Parts Ideal for Lights-Out Machining Using Swiss Machines

- High-Volume, Simple Parts: Parts that are produced in large quantities and require minimal complexity such as fasteners, washers, and screws.

- Parts with Consistent Geometry: Swiss machines excel at producing parts with high repeatability, ideal for simple geometries that don’t require frequent adjustments or manual intervention.

- Small, Precision Parts: Swiss machines are designed for small components that require tight tolerances used in medical, electronics, and aerospace.

- Parts that Don’t Require Frequent Tool Changes: Minimizing tool changes ensures uninterrupted runs during unattended shifts.

How to Prepare Swiss Machines for Lights-Out Machining

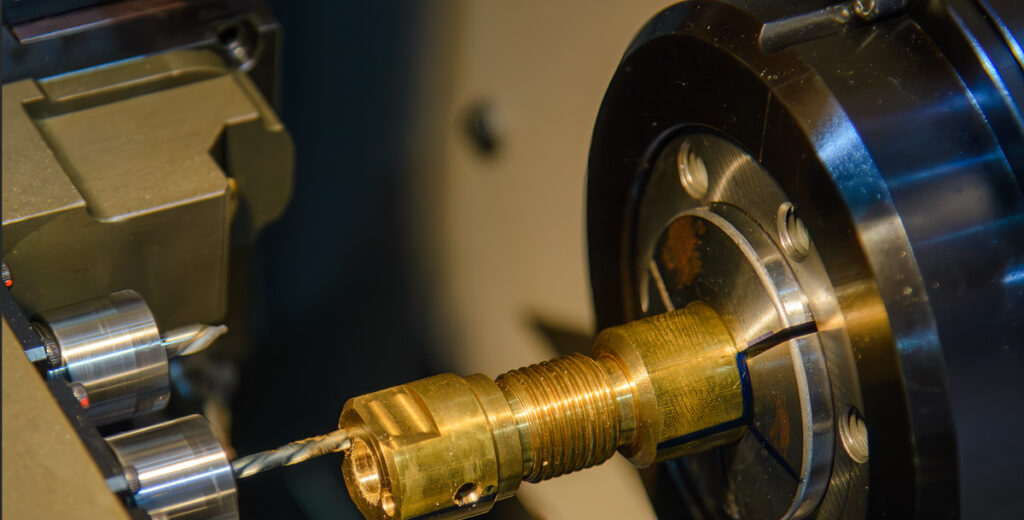

Tooling Setup: Sister Tooling and Redundant Tooling

Swiss machines are equipped with multiple toolholders, which is essential when running unattended. Sister tooling (or redundant tooling) is a crucial strategy to ensure the machine can continue running if one tool wears out or breaks.

- Sister Tooling: By using duplicate tools for critical operations, you can maintain uninterrupted machining. When one tool wears down, the second one takes over without requiring the operator to intervene.

- Tool Monitoring: Swiss machines can be equipped with tool monitoring systems to track wear and automatically notify you when tools need to be replaced or adjusted.

Setting Up Automatic Tool Changes Using Counters

One of the most effective ways to use sister tooling is by setting up tool life counters in the machine. Most Swiss machines allow you to program a counter for the number of parts produced, so the machine can automatically switch to the second tool once the first tool has reached its limit.

Example: Imagine you’re using a cutoff insert that typically needs to be changed after 1,000 parts. Instead of manually monitoring and changing the tool, you can place two identical cutoff inserts in separate toolholders and set the machine’s counter to switch to the second tool after 750 parts. This gives you a safety buffer, ensuring that the first tool won’t wear out completely during an unattended run. The machine will automatically switch to the second tool, avoiding any interruptions and maintaining consistent part quality throughout the night or weekend shift.

Programming Tips for Machining Lights-Out on Swiss Machines

- Optimize toolpaths to minimize idle time and balance cutting speed with tool longevity.

- Simulate and test programs to catch potential errors before running them unattended.

- Use long machining cycles for high-volume, repeatable parts to minimize interruptions.

Proper Tooling and Machine Maintenance

- Ensure all toolholders are secure and fixtures can hold parts tightly throughout the run.

- Pre-set tools and ensure special tools are ready in advance.

- Calibrate the machine to verify axes, spindles, and feeds are aligned correctly.

Monitoring and Remote Control Systems

- Remote Monitoring: Equip your Swiss machines with real-time monitoring systems to send alerts for any issues (e.g., tool wear, machine stoppages, part misfeeds).

- Data Collection: Use automated systems to track tool life, cycle time, and machine performance, allowing you to identify inefficiencies or problems early.

Safety Considerations

- Fire Suppression Systems: Install automatic fire suppression systems to respond quickly to overheating or fire during lights-out runs.

- Materials to Avoid: Avoid using materials prone to combustion, such as aluminum, magnesium, and brass, without safety protocols.

- Monitor Oil Levels: Ensure proper coolant levels to prevent oil mist ignition. Too little oil can create excess mist, increasing fire risk.

- Use a Mist Collector: A high-efficiency mist collector is crucial to reduce fire hazard and keep the machine environment clean.

- Machine Temperature and Ventilation: Monitor internal temperature, provide proper ventilation, and ensure cooling systems are in good working condition.

- Backup Systems: Set up emergency systems to stop the machine if heat, vibration, or fire suppression triggers are detected.

Key Takeaways for Lights-Out Machining with Swiss Machines

- Sister tooling and redundant setups are essential for uninterrupted operation.

- Smart programming and toolpath planning reduce the chance of failures during unattended machining.

- Regular maintenance and machine calibration ensure reliable long-term performance.

- Monitoring systems and safety backups are non-negotiable for effective lights-out runs.

Camco Precision: Mastering the Science of Lights-Out Machining and Swiss Machining

At Camco Precision Machining, we’ve perfected the science of Swiss machining lights-out capabilities. With years of experience, our team has fine-tuned every aspect of the process—from tooling setup and programming to machine monitoring and safety protocols. We understand the complexities and challenges of lights-out machining, and we’ve developed streamlined processes that ensure efficiency, consistency, and high-quality results every time.

Contact Us For Your CNC Machining Quote or to Learn More About Our Lights-Out Capabilities

At Camco Precision Machining, we specialize in Swiss machining and offer solutions that help increase efficiency through lights-out machining. Our team can help you optimize your Swiss machines for unattended production and provide the best results at the most cost-effective prices. Contact us today to learn more about our advanced Swiss machining services and how we can assist with your manufacturing needs and CNC machining quote with out cost-effective machining solutions!