High-Volume CNC Machining at Camco Precision Machining

At Camco Precision Machining, we specialize in high-volume machining services designed to meet the demands of industries requiring large quantities of precision parts with consistent quality, quick turnaround, and cost-effectiveness. With decades of experience and cutting-edge technology, we are built to handle production runs from tens of thousands of parts up to millions of pieces.

Whether you’re producing hydraulic components, automotive parts, electronics, firearms components, gear blanks, pneumatic fittings, fluid power parts, machined metal inserts for injection molding, or other types of machined parts, we have the capability to meet your needs with speed and precision.

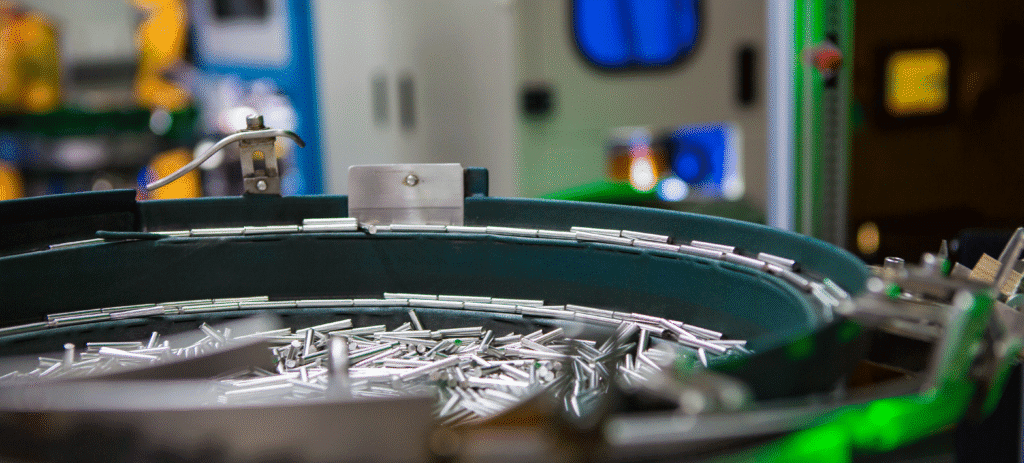

- Twin spindle machines are essential for high-volume production runs. This technology enables us to perform complex machining operations efficiently, reducing cycle times and increasing production speed. With the ability to run these machines 24/7, we ensure fast turnaround and superior results, maintaining high consistency across large runs.

- With automatic bar loading, we can maintain high throughput and quality, handling orders from tens of thousands up to millions of pieces. This system enhances the machining process, ensuring faster production without compromising quality.

- We maintain high throughput and precision by using automatic bar loading to support orders from tens of thousands to millions of parts—enhancing speed, reducing manual labor, and preserving quality across every run.

- Hydraulic: Valve bodies, piston rods, flow restrictors

- Automotive: Fuel injectors, brake components, suspension parts

- Electronics: Connectors, mounting brackets, heat sinks

- Firearms: Trigger components, magazine parts, barrel bushings

- Gear Blanks: Pinion gears, spur gears, bevel gears

- Pneumatic: Air cylinders, pneumatic valves, pressure regulators

- Fluid Power & Plumbing: Valve seats, pump components, nozzles

- Machined Metal Inserts for Injection Molding: Threaded inserts, heat-set inserts, standoffs

At Camco Precision Machining, we’re built to handle large production runs with precision, consistency, and speed. Here’s why we’re the ideal partner for your high-volume machining needs:

- Built for Large Runs – Our Swiss machining and screw machining capabilities are designed to produce tens of thousands to millions of parts, making us the perfect partner for bulk manufacturing.

- Consistency Across Large Runs – With advanced technology and automation, including automatic bar loading and twin spindle CNC turning, we maintain high levels of consistency and quality across all production runs, no matter how large.

- 24/7 Production Capability – Our ability to run machines around the clock allows us to meet your deadlines and ensure fast turnaround, giving you a competitive edge in fast-paced industries.

- Competitive Pricing – Our automated systems and efficient production processes ensure we can offer cost-effective solutions for high-volume machining. The combination of speed and efficiency keeps costs low, without sacrificing quality.

- Precision and Quality – We take great pride in our ability to produce parts to exacting tolerances. Whether it’s a high-precision hydraulic part or a gear blank, every part meets the highest standards of quality.

Request a Quote

Ready to get started on your high-volume machining project? Request a quote today and let Camco Precision Machining provide you with fast, accurate, and competitive pricing for your bulk production needs. Whether you need parts for hydraulics, automotive, electronics, or any other industry, we have the expertise and equipment to meet your high-volume production needs.

Industries Served

Precision shafts, Bushings, Small housings, Spacers, Retaining rings and more.

Pinion gears, Spur gears, Gear blanks for transmissions, Bevel gears, Worm gears and more.

Hydraulic valve bodies, Hydraulic pistons, Connectors, O-ring grooves, Flow restrictors and more.

Surgical instruments, Dental implant components, Robotic arm joints, Guide pins, Needle holders and more.

Aircraft fasteners, Brackets, Actuator components, Precision bushings, Aerospace gear blanks and more.

Fuel injectors, Valve bodies, Transmission parts, Brake components, Suspension bushings and more.

Connectors, Mounting brackets, Heat sinks, PCB components, Electrical terminals and more.

Trigger components, Magazine parts, Barrel bushings, Firing pins, Gun receiver components and more.

Valve seats, Pump components, Seals and gaskets, Nozzles, Couplings and more.

Threaded inserts, Heat-set inserts, Retaining rings, Standoffs, Bushings and more.

Valve components, Pressure seals, Pump shafts, Manifold parts, Couplings and more.

Air cylinders, Pressure regulators, Pneumatic valves, Piston rods, Air fittings

Ask a Question

Camco Precision Machining

4701 Haag Drive

Union Grove, WI 53182

262-878-4700

Local to Wisconsin and Chicago, Shipping Quality Machined Parts Nationwide Since 1981.