Gear Blank Machining

Gear Blank Machining

At Camco Precision Machining, we have decades of experience in precision gear blank machining, providing high-quality gear blanks for a wide variety of industries. Our extensive expertise, combined with cutting-edge machining technologies, makes us a trusted partner for customers who require custom gear blanks with tight tolerances and superior performance.

Whether you need low or high-volume production runs, we are equipped to deliver the highest quality gear blanks that meet your unique specifications. Our focus on precision machining, material flexibility, and efficient production ensures that we exceed your expectations on every project.

What Are Gear Blanks?

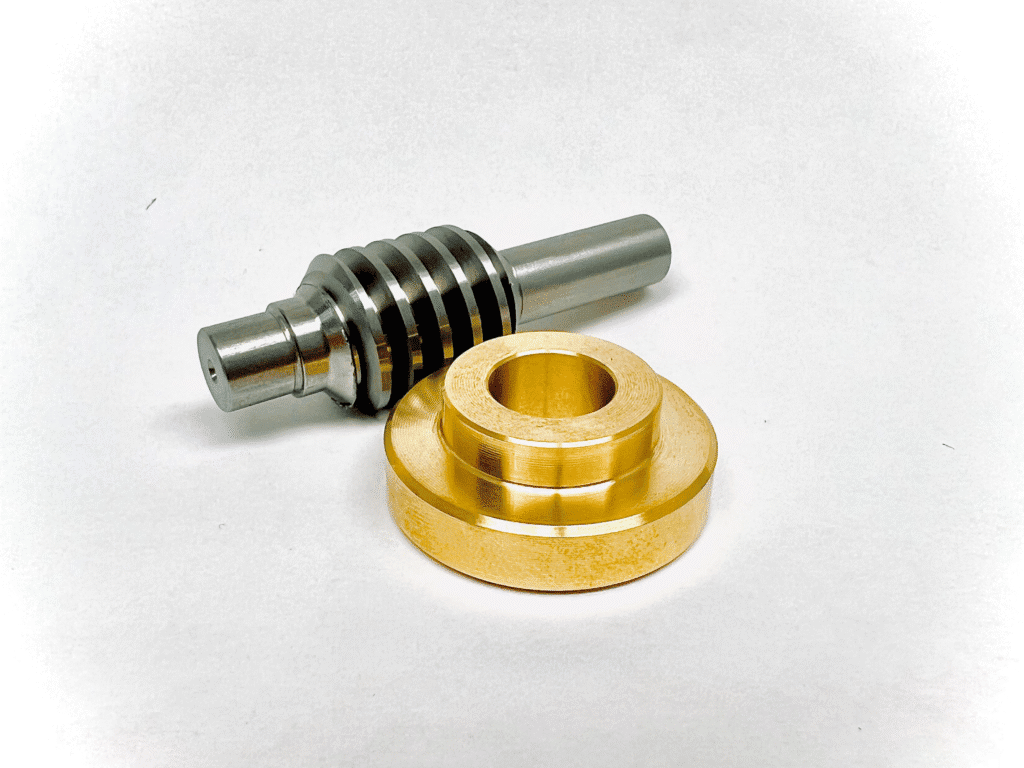

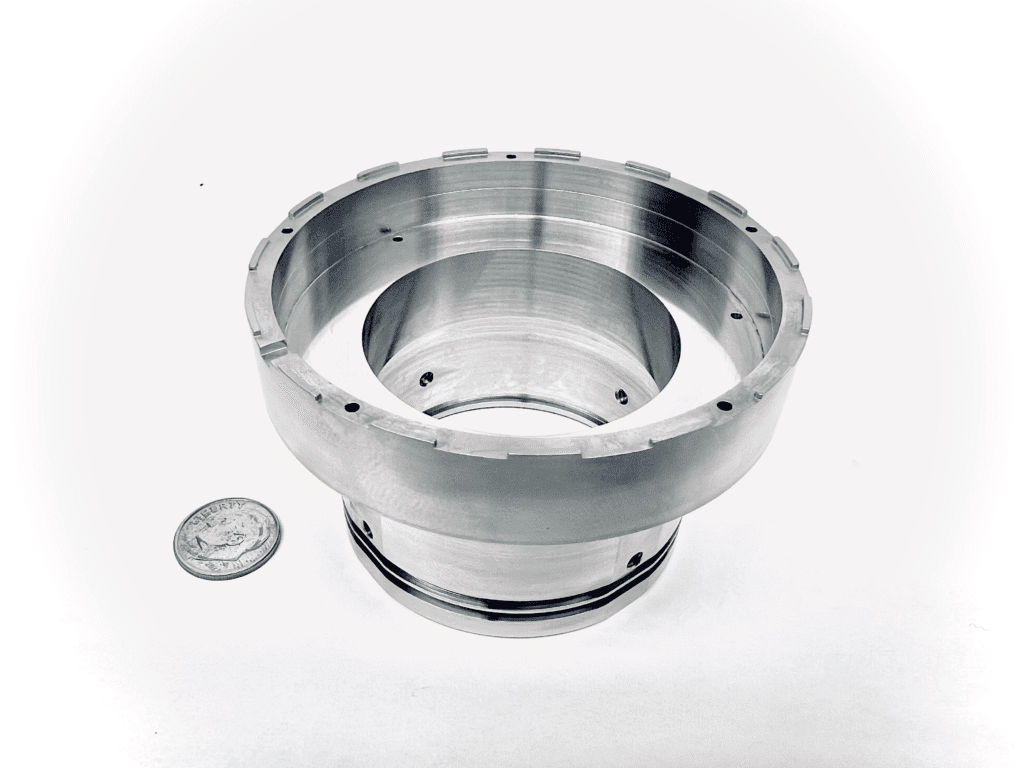

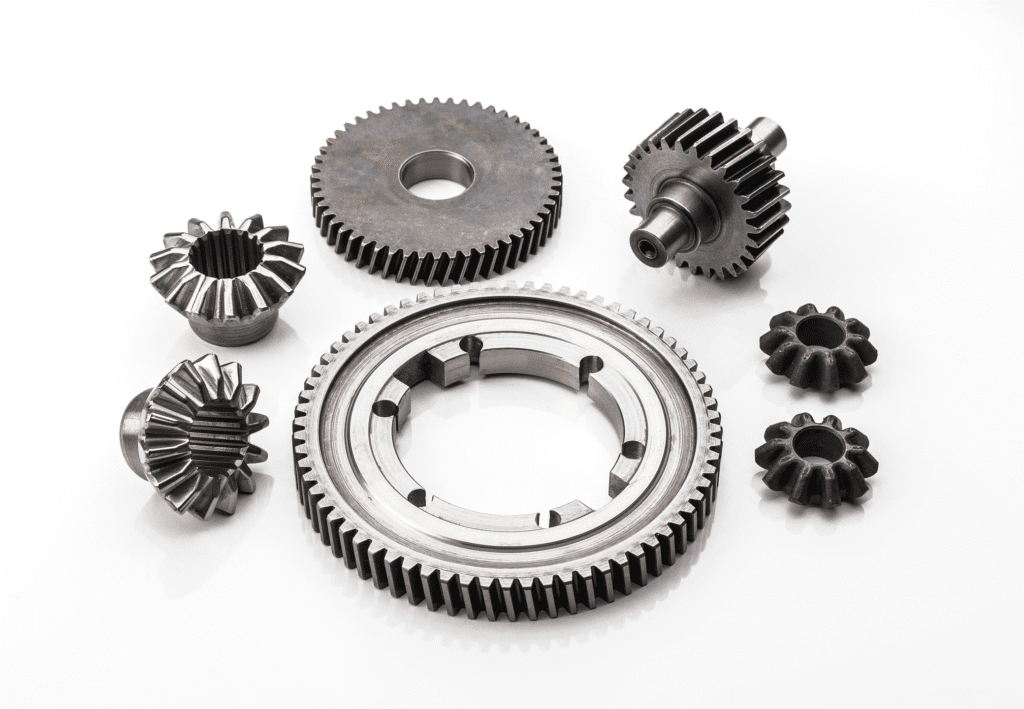

A gear blank is a solid, CNC-machined piece of material that serves as the foundational starting point for gear production. These blanks are precisely cut to exact dimensions and can be further processed to meet the specific requirements of your application. Gear blanks are essential for industries that demand highly durable and accurate components, and we specialize in crafting blanks that deliver excellent performance in a range of gear applications.

At Camco Precision Machining, we have extensive experience working with a wide variety of materials, including bronze, brass, fatigue-proof steel, stainless steel, carbon steel, aluminum, and more. Whether you need a small gear blank down to below 1/16″ in diameter or large blanks up to 14″, we have the expertise to deliver custom blanks in the exact size and material that your project requires.

At Camco Precision Machining, we are a custom gear manufacturer that utilizes CNC machining to produce high-quality gear blanks with both simple and complex features. We offer turned and milled features to ensure each blank meets the precise requirements of our customers, such as gear houses and gear companies. Whether the blanks are straightforward or require intricate geometries, our advanced CNC machining processes ensure accuracy and consistency across every part.

We also utilize Swiss machining for manufacturing the blanks, allowing us to provide high-precision, custom gear blanks for both small and large production runs. Our advanced machinery ensures that we can handle a wide range of sizes and geometries, providing you with blanks that meet your exact specifications.

We work with customers to supply furnished gear blanks that are ready for further processing, meaning we deliver blanks that fit the specifications of your gear manufacturing needs.

Our gear blank machining process is designed to maximize precision and efficiency, ensuring that each blank meets the highest standards of quality. Here’s a breakdown of the steps involved:

- Material Handling: We work with materials such as bronze, brass, fatigue-proof steel, stainless steel, carbon steel, and aluminum. Each is selected to best suit your project’s needs for optimal performance.

- CNC Machining: Using CNC turning and milling, we produce gear blanks with a variety of features—from simple bores to complex geometries—meeting exact specs for machined gears.

- Multi-Spindle Turning: Ideal for high-volume production, our multi-spindle turning reduces cycle times while maintaining high precision, delivering cost-effective manufacturing.

- Geometric Control: We ensure parallelism, perpendicularity, and concentricity throughout machining, using GD&T standards to guarantee form and fit requirements are met.

- Rigorous Inspection: Every gear blank undergoes dimensional inspection using CMM technology to verify features like diameters, perpendicularity, and runout accuracy.

- Fully Custom Blanks: From material to geometry, we manufacture custom gear blanks to your exact specifications for performance, durability, and reliability.

- High Precision & Tight Tolerances: We deliver gear blanks with exceptional accuracy, maintaining tight tolerances for critical features like parallelism, perpendicularity, and concentricity.

- Material Flexibility: Experienced with bronze, brass, fatigue-proof steel, stainless steel, carbon steel, and aluminum to match your exact needs.

- Versatile Sizing: Capable of machining gear blanks from below 1/16″ up to 14″, suitable for a wide variety of applications.

- Advanced Machining Capabilities: We combine turning, milling, Swiss, and multi-spindle machining for superior flexibility and performance.

- Cost-Effective Production: Multi-spindle turning and optimized workflows help reduce costs across production volumes.

- Quality Assurance: In-house inspections and rigorous quality standards ensure consistent, high-performance parts.

- Fast Lead Times: Equipped facility and expert team allow for quick turnarounds to keep your projects moving.

Our precision gear blanks are used across a broad range of industries, including:

- Automotive: Gears used in transmissions, engines, and drivetrains where durability and precision are critical.

- Aerospace: Components in flight systems requiring high tolerances and material strength.

- Industrial Machinery: Gears for robotics, conveyors, and heavy-duty equipment.

- Agricultural Equipment: High-stress parts for rugged farming machinery.

- Energy & Power Generation: Gear blanks for turbines and other high-performance applications.

- And More: Including medical devices, marine equipment, and consumer goods.

Request a Quote

At Camco Precision Machining, we are committed to providing you with high-performance, precision-machined parts that meet the highest standards for your industry. Contact us today to request a competitive quote and learn more about how we can support your next project with reliable and high-quality parts.

Learn more about partners we have worked with here >

Machining Capabilities

High-precision parts using advanced CNC Swiss machines.

Orders up to 1,000,000+ pieces efficiently produced.

Continuous, automated production from metal bar stock.

Multi-spindle lathes with live tooling for complex parts.

Enhanced efficiency and cost savings for high-volume runs.

Versatile machining for complex shapes and features.

Connectors, Mounting brackets, Heat sinks, PCB components, Electrical terminals and more.

Trigger components, Magazine parts, Barrel bushings, Firing pins, Gun receiver components and more.

Valve seats, Pump components, Seals and gaskets, Nozzles, Couplings and more.

Threaded inserts, Heat-set inserts, Retaining rings, Standoffs, Bushings and more.

Valve components, Pressure seals, Pump shafts, Manifold parts, Couplings and more.

Air cylinders, Pressure regulators, Pneumatic valves, Piston rods, Air fittings

Keep up with the latest news and technology in the CNC machining industry by visiting the Precision Machined Products Association. >

Ask a Question

Camco Precision Machining

4701 Haag Drive

Union Grove, WI 53182

262-878-4700

Local to Wisconsin and Chicago, Shipping Quality Machined Parts Nationwide Since 1981.