CNC Turning

At Camco Precision Machining, we specialize in high-quality CNC turning services to produce precision-machined components for a variety of industries. With over 40 years of experience, we provide expert lathe machining capabilities to meet your exact specifications, delivering high-precision parts with the efficiency and cost-effectiveness that your business requires. We also utilize automatic bar loaders and magazine barfeeders, which enhance machining efficiency and reduce downtime by automatically loading material, allowing for continuous production without manual intervention.

What is CNC Turning?

CNC turning is a versatile machining process where a part is rotated while a cutting tool is applied to the surface to remove material and shape the part. This process is perfect for creating cylindrical, conical, and other symmetrical shapes. CNC turning is highly effective for producing high-volume, repeatable parts with tight tolerances. At Camco Precision Machining, we use advanced CNC turning lathes to ensure that every part is made with precision, resulting in superior quality and consistency.

Our CNC turning machines can handle a wide range of materials, including stainless steel, aluminum, brass, and more. Whether you need simple or complex components, our machines are equipped with live tooling and multi-spindle capabilities, allowing us to execute multi-axis turning for more intricate geometries, improving both the speed and accuracy of production.

Live Tooling: Enhanced Machining Capabilities

One of the key features of our CNC turning machines is live tooling. This capability allows the machine to perform additional operations, such as drilling, milling, and tapping, while the part is still rotating. Live tooling minimizes the need for secondary operations, reduces part handling, and shortens cycle times, leading to more efficient production and higher accuracy in your parts. This makes our CNC turning process more versatile and capable of producing complex geometries with fewer setups, saving you time and costs.

Multi-Spindle Machines: Streamlined Efficiency and Cost Savings

At Camco Precision Machining, our multi-spindle CNC turning machines allow us to perform multiple operations in a single setup. This capability eliminates the need for multiple setups, reducing part handling and improving workflow efficiency.

By consolidating operations into a single setup, we minimize the time spent on machine adjustments and part transfers. This not only reduces labor requirements but also decreases the chances for errors, resulting in higher precision and faster turnaround times. The streamlined process leads to significant cost savings for our customers, making us a preferred choice for high-volume, cost-efficient machining.

- Aerospace: Precision-engineered components for aerospace applications.

- Automotive: Machined parts for automotive systems and accessories.

- Medical Devices: Small, precise parts for medical device manufacturers.

- Electronics: Precision components for the electronics industry.

- Hydraulics: Turned parts for hydraulic systems.

- Gear Blanks: High-precision gear blanks for a variety of industries.

- And more: Serving a wide range of industries, from industrial machinery to energy and beyond.

- High Precision: Achieve tight tolerance CNC turned parts and consistent quality without fail.

- High Efficiency: Our CNC turning machines allow for faster cycle times and reduced setup time, resulting in more competitive pricing.

- Versatility: Capable of handling complex geometries, multi-axis turning, and various materials.

- Cost-Effective: CNC turning allows for faster production runs and reduced manual labor, passing on cost savings to our customers.

Swiss & Screw Machining in Turning Operations

Swiss machining and screw machining are specialized forms of turning that excel in high-precision and high-volume production of small parts. While they are both technically forms of turning, they provide additional benefits for parts requiring extreme accuracy and complex features.

- Swiss Machining: Ideal for parts that require small diameters, intricate features, or high precision. Swiss machines use a sliding headstock to allow parts to be fed through the machine continuously, making them perfect for high-volume production.

- Screw Machining: This process is used for high-speed production of small, threaded parts. With our multi-spindle screw machining capabilities, we can produce parts faster and with greater cost efficiency, particularly for high-volume orders.

Both Swiss and screw machining offer additional versatility for turning operations, enabling us to meet the demands of complex, tight-tolerance parts with faster cycle times and reduced material waste.

Why Partner with Camco for CNC Turning

- Experienced Team: Our skilled machinists have decades of experience in CNC turning, ensuring that your parts are made to the highest standards.

- State-of-the-Art Equipment: We invest in the latest CNC turning lathes and machining technologies to provide the best results.

- Quick Turnaround: We prioritize speed and efficiency, ensuring your high-volume orders are completed on time without sacrificing quality.

- Competitive Pricing: With advanced machinery and efficient processes, we offer some of the most competitive pricing in the industry.

Request a Quote

At Camco Precision Machining, we are committed to providing you with high-performance, precision-machined parts that meet the highest standards for your industry. Contact us today to request a competitive quote and learn more about how we can support your next project with reliable and high-quality custom CNC turning solutions.

Get a Quote for Your CNC Turning Project

If you are looking for high-quality, precision-machined parts with CNC turning, Swiss, or screw machining, Camco Precision Machining is the right choice for your needs. Our team is here to assist you with all your machining requirements. Get in touch with us today for a fast, accurate quote!

Industries Served

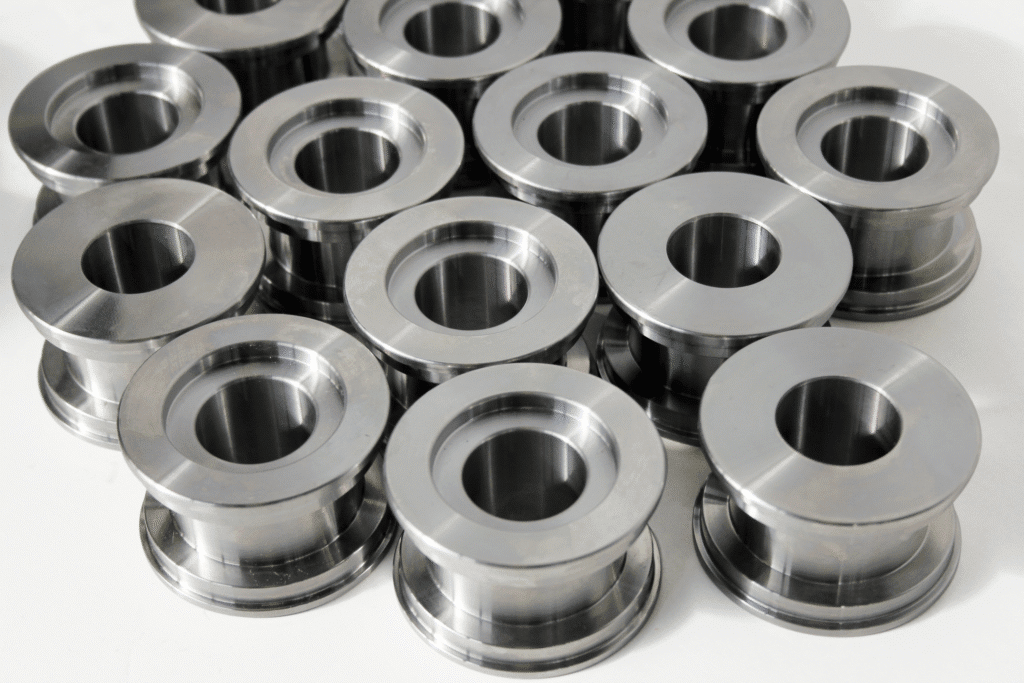

Precision shafts, Bushings, Small housings, Spacers, Retaining rings and more.

Pinion gears, Spur gears, Gear blanks for transmissions, Bevel gears, Worm gears and more.

Hydraulic valve bodies, Hydraulic pistons, Connectors, O-ring grooves, Flow restrictors and more.

Surgical instruments, Dental implant components, Robotic arm joints, Guide pins, Needle holders and more.

Aircraft fasteners, Brackets, Actuator components, Precision bushings, Aerospace gear blanks and more.

Fuel injectors, Valve bodies, Transmission parts, Brake components, Suspension bushings and more.

Connectors, Mounting brackets, Heat sinks, PCB components, Electrical terminals and more.

Trigger components, Magazine parts, Barrel bushings, Firing pins, Gun receiver components and more.

Valve seats, Pump components, Seals and gaskets, Nozzles, Couplings and more.

Threaded inserts, Heat-set inserts, Retaining rings, Standoffs, Bushings and more.

Valve components, Pressure seals, Pump shafts, Manifold parts, Couplings and more.

Air cylinders, Pressure regulators, Pneumatic valves, Piston rods, Air fittings

Ask a Question

Camco Precision Machining

4701 Haag Drive

Union Grove, WI 53182

262-878-4700

Local to Wisconsin and Chicago, Shipping Quality Machined Parts Nationwide Since 1981.