Equipment List And Capacities

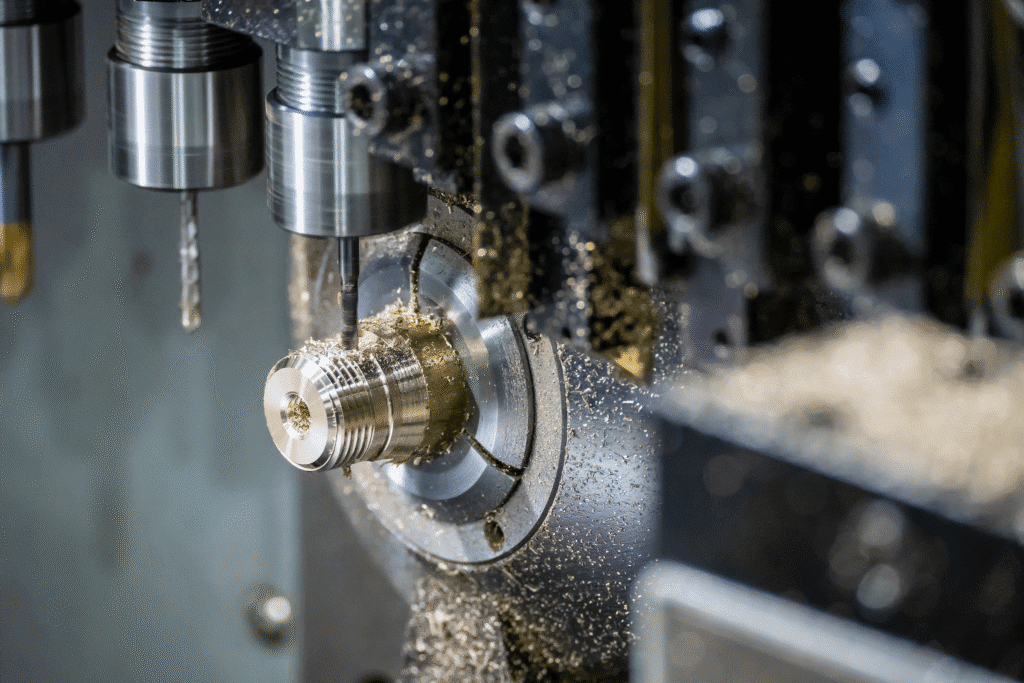

Equipment and Machining Capacities for CNC Machining Small Parts

At Camco Precision Machining, we use advanced machinery to deliver precision machining across a range of services. Below are the key capabilities of our machines, ensuring that we meet the needs of various industries while maintaining high standards of quality and accuracy, and tight tolerance machining.

Summary of Capacities

| Machining Service | Machine Brand | Capacity / Technical Information |

|---|---|---|

| Swiss & Screw Machining | Star | Up to Ø1.250" (32mm), part lengths up to 54” (or longer) |

| CNC Turning | Okuma | Ø3” thru-spindle, Ø14” chucking |

| CNC Milling | Haas | Table size: 50” x 20”; X/Y/Z travel: 50"/20"/25"; 4-axis capabilities |

We specialize in Swiss and screw machining using Star machines, known for their precision and ability to handle small-diameter components. Our capabilities include machining parts up to Ø1.250" (32mm) in diameter and 54” in length (or longer depending on the part).

- Capacity: Up to Ø1.250" (32mm) and part lengths up to 54”

- Number of Axes: 7 axes for multi-dimensional operations

-

Technical Features:

- Live tooling – Performs secondary operations (drilling, tapping, milling) while rotating

- Sub-spindles – Enhances efficiency and reduces setup time

- Automatic magazine bar loaders – Boosts productivity and enables uninterrupted long-run operations

These machines produce complex, tight-tolerance components such as shafts and threaded parts, ideal for aerospace, medical, automotive industries and micro machining.

Our Okuma lathes provide flexibility and precision in turning operations. These machines are equipped with live tooling and sub-spindles, enabling us to perform multiple operations in a single setup, reducing cycle times and improving efficiency.

-

Capacity:

- Ø3” (76mm) thru-spindle capacity

- Ø14” (355mm) chucking capacity

- Number of Axes: 4-axis with live tooling and sub-spindles

-

Technical Features:

- Live tooling – Allows for milling, drilling, and tapping without the need for secondary setups

- Sub-spindles – Enable parts to be completed without re-chucking, improving part consistency and production efficiency

- Automatic magazine bar loaders – Enhance efficiency and reduce downtime during long production runs

These machines are ideal for a range of applications, from small precision components to larger, high-torque parts.

Our Haas milling machines are used for producing precision components across a wide range of materials. With advanced technology, these machines ensure efficiency and accuracy, particularly for parts requiring detailed multi-dimensional machining.

-

Capacity:

- Table size: 50” x 20”

- X-axis travel: 50”

- Y-axis travel: 20”

- Z-axis travel: 25”

- Number of Axes: 4-axis capabilities

-

Technical Features:

- High-speed machining – Ideal for precision parts in aerospace, automotive, and electronics industries

- Automated tool changers – Ensure consistent and efficient operations

- 4th-axis capabilities – Enable more complex machining without repositioning parts

These milling machines are ideal for precision work that requires flexibility and high accuracy, allowing us to handle both prototypes and high-volume production runs.

Vision System & CMM Probing

At Camco Precision Machining, precision and consistency are integral to every part we produce. To maintain the highest standards of quality, we utilize advanced vision system and CMM probing technology, ensuring that every part meets the exact specifications and tolerances required by our clients.

Vision system and CMM probing capabilities:

Our vision system provides high-precision, non-contact measurement for inspecting surface features and dimensional accuracy. This system offers exceptional repeatability and is capable of measuring parts with micron-level accuracy. It is ideal for inspecting complex geometries, verifying alignment, and detecting even the smallest deviations from specified dimensions.

In conjunction with the vision system, our CMM probing system allows for precise 3D measurement of parts. The CMM system provides detailed data on part geometry, ensuring that all features are within tolerances. The combination of vision system and CMM probing allows us to inspect parts in real time, significantly reducing the risk of defects while improving the overall efficiency of the production process.

Key Capabilities:

- Vision System – Offers sub-micron accuracy and exceptional repeatability for surface feature and dimensional inspections

- CMM Probing – Provides 3D measurement capabilities with high accuracy, ensuring that complex parts meet precise tolerances

- Measurement Range – Capable of inspecting both small and large parts with high levels of accuracy

- Repeatability – Ensures consistent results across production runs through advanced system stability

- Accuracy – Maintains tight tolerances throughout the machining process, critical for high-precision industries

By incorporating the vision system and CMM probing into our quality control processes, we ensure the highest level of precision and consistency in every part we manufacture. These advanced capabilities enable us to meet the exacting standards of industries such as aerospace, automotive, and electronics.

Industries Served

Precision shafts, Bushings, Small housings, Spacers, Retaining rings and more.

Pinion gears, Spur gears, Gear blanks for transmissions, Bevel gears, Worm gears and more.

Hydraulic valve bodies, Hydraulic pistons, Connectors, O-ring grooves, Flow restrictors and more.

Surgical instruments, Dental implant components, Robotic arm joints, Guide pins, Needle holders and more.

Aircraft fasteners, Brackets, Actuator components, Precision bushings, Aerospace gear blanks and more.

Fuel injectors, Valve bodies, Transmission parts, Brake components, Suspension bushings and more.

Connectors, Mounting brackets, Heat sinks, PCB components, Electrical terminals and more.

Trigger components, Magazine parts, Barrel bushings, Firing pins, Gun receiver components and more.

Valve seats, Pump components, Seals and gaskets, Nozzles, Couplings and more.

Threaded inserts, Heat-set inserts, Retaining rings, Standoffs, Bushings and more.

Valve components, Pressure seals, Pump shafts, Manifold parts, Couplings and more.

Air cylinders, Pressure regulators, Pneumatic valves, Piston rods, Air fittings

Ask a Question

Camco Precision Machining

4701 Haag Drive

Union Grove, WI 53182

262-878-4700

Local to Wisconsin and Chicago, Shipping Quality Machined Parts Nationwide Since 1981.