General CNC Machining

High-Precision CNC Machining

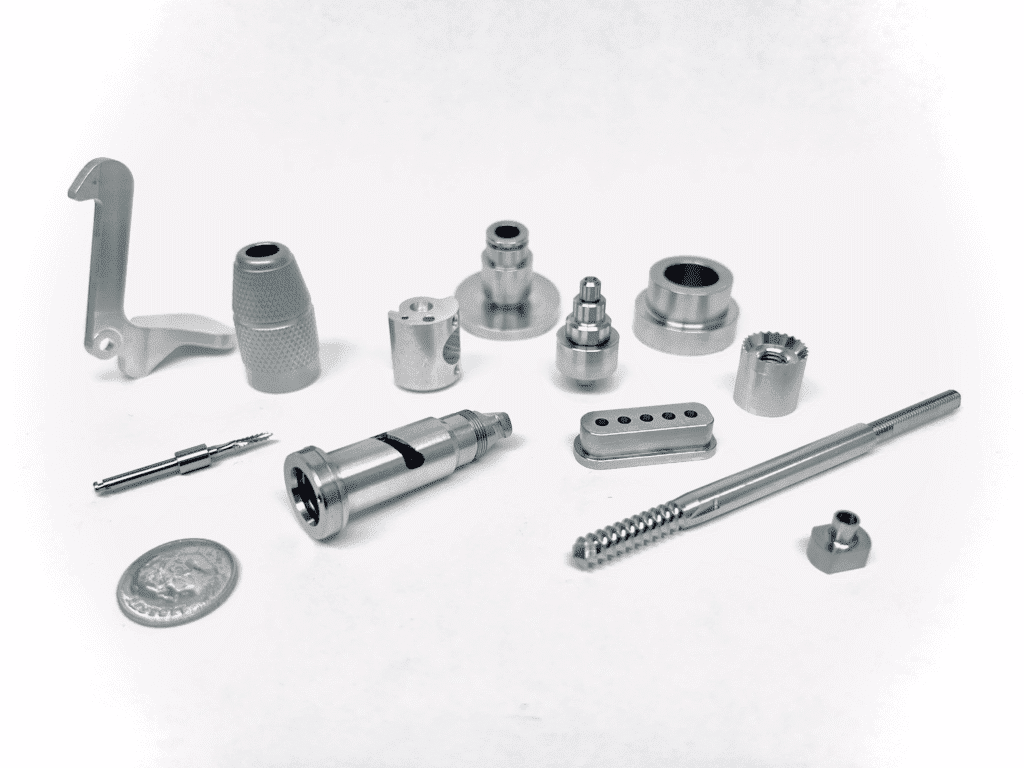

At Camco Precision Machining, we specialize in providing CNC machined parts and solutions using advanced technologies such as CNC lathes, CNC milling, Swiss machining, and screw machining. With over 40 years of experience, we deliver precise, cost-effective, and reliable machining services for industries requiring everything from small, intricate components to large, high-performance parts. Whether you require high-volume production or custom parts, we ensure consistent quality and tight tolerances.

We offer a wide range of CNC machining services to meet the diverse needs of OEM manufacturers across multiple industries. Our turning capacity ranges from under Ø1/16″ up to Ø14″, allowing us to accommodate a broad variety of machining requirements, including:

- High-precision components for automotive, medical devices, aerospace, and industrial machinery.

- Custom machining solutions for parts ranging from small fasteners to large-scale parts.

We are also equipped to handle both mid and high-volume production runs, producing orders from 250 pieces to 1,000,000+ pieces, ensuring your production needs are met with efficiency and consistency.

As a Swiss machining supplier, our high-volume production capabilities are particularly well-suited for industries such as automotive, aerospace, medical devices, and industrial equipment. We use advanced CNC Swiss machines and multi-spindle CNC lathes to produce parts that require both precision and bulk production efficiency. These machines excel at creating small, complex parts such as:

- Fasteners, screws, and small threaded components used in electronics, medical devices, and automotive applications.

- Shafts for medical devices, automotive systems, and aerospace components.

Our screw machining and Swiss machining techniques allow us to handle both complex geometries and high-volume production, ensuring quick turnaround times without compromising on quality.

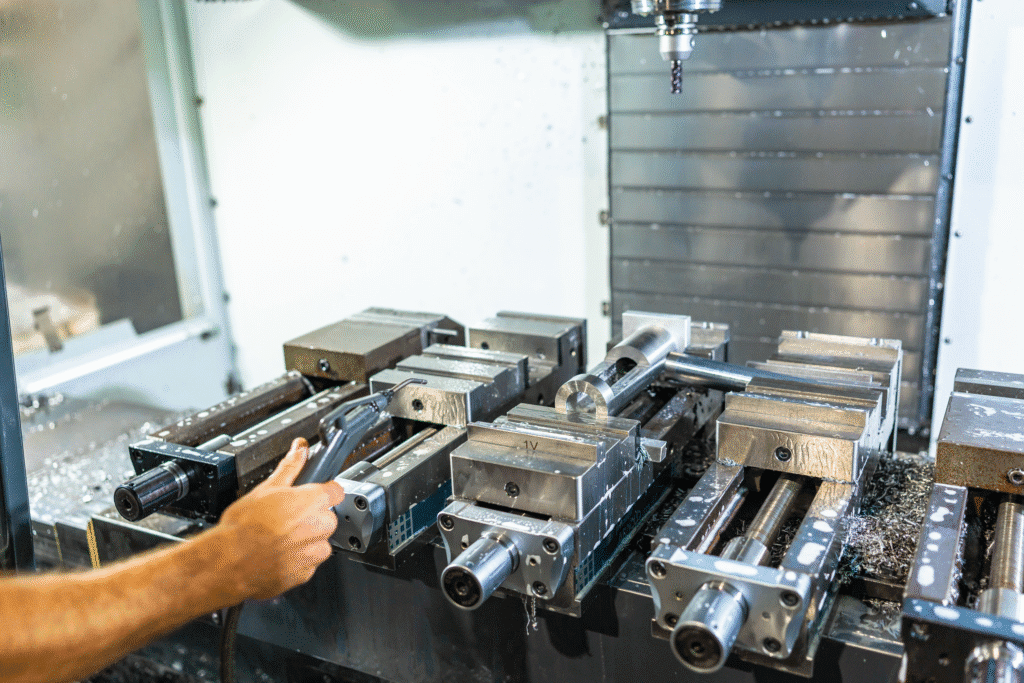

At Camco Precision Machining, we are equipped with state-of-the-art technology to handle both turning and milling operations in a single setup, reducing production time and ensuring tight tolerances. Our multi-spindle CNC lathes, equipped with live tooling, are ideal for high-volume production of complex parts. These machines are perfect for parts such as:

- Gear blanks, valve components, electrical connectors, and other intricate parts required by industries like automotive, aerospace, and medical devices.

- Custom machined components for high-performance applications, including medical shafts, aerospace connectors, and automotive parts.

Whether you need custom parts or bulk production runs, our multi-spindle CNC lathes and Swiss machines ensure precision and speed, making them ideal for large-scale manufacturing.

We work with a wide range of materials to meet the demands of various industries, including:

- Aluminum Alloys – Used in lightweight applications such as automotive parts, aerospace components, and industrial machinery.

- Stainless Steel – Known for its strength and corrosion resistance, used in medical devices, hydraulic components, and aerospace parts.

- Brass and Bronze – Ideal for electrical connectors, fasteners, and fittings.

- Titanium – High-strength and lightweight, commonly used in aerospace, automotive, and medical devices.

- Steel Alloys – Used for high-stress components such as gears, shafts, and valves.

- Plastics – Used for non-metallic parts in medical devices, electronics, and consumer products.

Our expertise in working with these materials ensures that each part is produced with the optimal material selection for its intended application, ensuring performance, durability, and reliability.

At Camco Precision Machining, we understand that precision is critical, especially in industries like aerospace, medical devices, and automotive systems. We ensure that every part meets OEM specifications and industry standards. Typical tolerances we achieve include:

- Dimensional tolerances as tight as ±0.0001 inches.

- Geometrical tolerances such as perpendicularity, parallelism, positional tolerances, and profile as per GD&T (Geometric Dimensioning and Tolerancing).

- Surface finishes that meet RA (Roughness Average) requirements as low as 32 microinches.

- Thread tolerances for tight-fitting bolts, nuts, and screws used in high-performance applications.

We employ rigorous quality control measures to ensure that each part meets the exacting standards of our customers. This commitment to quality extends to our high-volume production runs, where we maintain consistency and precision across thousands or millions of parts.

- Expertise with OEMs – Extensive experience producing custom metal parts that meet the most demanding performance and safety standards.

- State-of-the-Art CNC Technology – Swiss machines, multi-spindle CNC lathes, milling machines, and screw machining capabilities for high-volume, tight-tolerance production.

- Material Expertise – Skilled in machining aluminum, stainless steel, titanium, and plastics to ensure performance under extreme conditions.

- Quality Assurance – Strict quality control ensures every part meets OEM specifications and delivers reliable performance.

- On-Time Delivery – Committed to meeting production timelines for bulk orders without compromising quality.

ITAR Compliant and Serving Critical Industries

Camco Precision Machining is ITAR compliant, ensuring that all parts are produced with the highest levels of security and confidentiality for industries that require strict adherence to regulatory standards. We proudly serve critical industries including aerospace, defense, and medical devices, where precision, reliability, and compliance with industry regulations are paramount.

Our ITAR compliance and industry-specific expertise make us a trusted partner for OEMs requiring precision machining services for high-performance parts in critical applications.

Request a Quote for CNC Machining Parts

If you are looking for precision CNC machining, custom automotive components, high-volume production runs, or other precision parts for OEM applications, ask a question or request a quote below. Let us help you meet the demanding standards of the automotive, aerospace, medical, and defense industries with reliable, high-performance parts, ideal for high-volume and bulk production.

Machining Capabilities

High-precision parts using advanced CNC Swiss machines.

Orders up to 1,000,000+ pieces efficiently produced.

Continuous, automated production from metal bar stock.

Multi-spindle lathes with live tooling for complex parts.

Enhanced efficiency and cost savings for high-volume runs.

Versatile machining for complex shapes and features.

Connectors, Mounting brackets, Heat sinks, PCB components, Electrical terminals and more.

Trigger components, Magazine parts, Barrel bushings, Firing pins, Gun receiver components and more.

Valve seats, Pump components, Seals and gaskets, Nozzles, Couplings and more.

Threaded inserts, Heat-set inserts, Retaining rings, Standoffs, Bushings and more.

Valve components, Pressure seals, Pump shafts, Manifold parts, Couplings and more.

Air cylinders, Pressure regulators, Pneumatic valves, Piston rods, Air fittings

Keep up with the latest news and technology in the CNC machining industry by visiting the Precision Machined Products Association. >

Ask a Question

Camco Precision Machining

4701 Haag Drive

Union Grove, WI 53182

262-878-4700

Local to Wisconsin and Chicago, Shipping Quality Machined Parts Nationwide Since 1981.