Top 5 Benefits of Swiss Machining: The Precision Solution for Complex Parts

Swiss machining has become an essential manufacturing process for industries that require high precision, tight tolerances, and the ability to produce complex geometries.

Whether you’re manufacturing parts for aerospace, medical devices, or automotive applications, Swiss machining provides the accuracy and efficiency you need to stay ahead of the competition.

In this article, we will dive into the top 5 benefits of Swiss machining and explore when it’s the right choice for your production needs, as well as when it may not be the best option.

What is Swiss Machining?

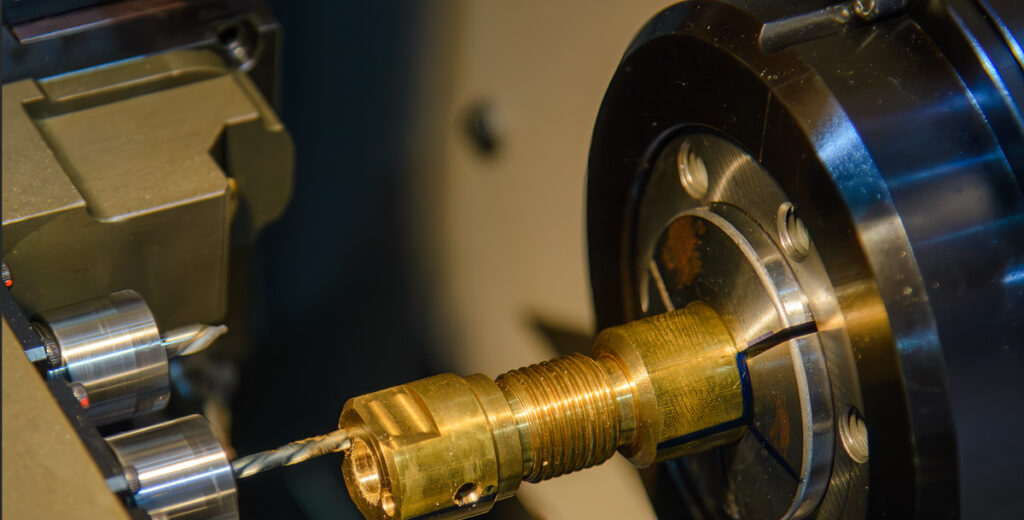

Swiss machining, also known as Swiss-type turning, is a specialized CNC turning process that uses a sliding headstock to hold the workpiece in place while it moves along multiple axes. The machine’s toolholders perform turning, milling, and drilling operations simultaneously, allowing for the production of highly intricate, small parts that require extreme precision.

This method is ideal for high-volume production and for producing parts with complex features that need to be machined from multiple angles in a single setup.

Top 5 Benefits of Swiss Machining

- Exceptional Precision and Tight Tolerances

Swiss machining is renowned for its exceptional precision. The process allows manufacturers to hold tolerances as tight as ±0.0001 inches (0.0025 mm). This is critical in industries such as aerospace, medical devices, and electronics, where even the slightest deviation can result in major issues. Swiss machining provides a level of accuracy that is hard to achieve with other machining methods, making it the go-to solution for parts that need to meet stringent quality standards.

- Increased Efficiency and Reduced Setup Time

Swiss machining is not only known for its reduced setup times, but it also excels at eliminating multiple lathe setups. Traditional machining methods often require several setups to complete a part, leading to longer production cycles. However, Swiss machining allows for the production of complex parts in a single setup, reducing the need for repositioning the workpiece and multiple machine changeovers.

What’s more, Swiss machines equipped with live tooling allow for milling operations to be performed alongside turning. This eliminates the need for a separate milling machine and drastically reduces production time by completing both turning and milling operations in one machine, streamlining the entire process. Additionally, automatic bar feeders are commonly used with Swiss machines, which minimize manual intervention and reduce downtime, leading to even greater time savings.

- Ability to Produce Complex Part Geometries

One of the key advantages of Swiss machining is its ability to create highly complex part geometries that would be difficult to achieve with traditional machining methods. Swiss machines can simultaneously perform operations like turning, milling, and drilling, allowing for intricate features like threaded holes, angled surfaces, and slots to be created in one operation. This capability allows for greater design flexibility and fewer operations than traditional methods.

- Cost-Effective for High-Volume Production

While Swiss machining equipment can be expensive, it becomes cost-effective for high-volume production runs. The ability to perform multiple operations in one setup, combined with reduced labor and setup time, makes Swiss machining an ideal choice for producing thousands or millions of parts. The high automation and low setup time lead to increased productivity and more affordable parts for your customers.

- Extended Tool Life and Reduced Material Waste

Swiss machining provides several advantages in terms of tool life and material usage. Due to the precision of the process, parts are typically machined correctly on the first pass, minimizing scrap material and tool wear. This accuracy leads to lower material costs and longer tool life, contributing to overall cost savings.

Swiss Machining vs. Traditional CNC Machining: A Comparison

| Feature | Swiss Machining | Traditional CNC Machining |

|---|---|---|

| Precision | High precision (down to microns) | Moderate precision |

| Complexity | Ideal for intricate, small parts | Better for simpler, larger parts |

| Setup Time | Faster setup, fewer changeovers | Longer setup time for complex parts |

| Production Volume | Excellent for high-volume runs | Better suited for low to medium volumes |

| Cost-Effectiveness | Cost-effective for high volume | Expensive for high volume |

Industries That Benefit from Swiss Machining

Swiss machining is widely used across various industries that require precision, high quality, and efficiency. Here are just a few examples of industries that benefit from Swiss machining:

- Aerospace: Manufacturing high-precision components for engines, fasteners, and brackets.

- Medical Devices: Creating intricate components for implants, surgical instruments, and diagnostic tools.

- Automotive: Producing parts like connectors, sensors, and fasteners.

- Electronics: Crafting small, delicate components such as capacitors, connectors, and switches.

- Fluid Power: Producing durable and precise components for valves, pumps, and other hydraulic and pneumatic systems.

Key Takeaways: Why Swiss Machining is a Game-Changer

Swiss machining is an invaluable tool for producing high-precision, complex components with tight tolerances. Here’s why you should consider Swiss machining:

- Precision and Accuracy: Ideal for industries that require high-quality parts with tight tolerances.

- Increased Efficiency: Reduces setup times and increases production speed, especially for high-volume production.

- Complex Geometries: Capable of producing intricate parts that would be difficult or impossible to create with other methods.

- Cost Savings: Reduces material waste, extends tool life, and automates processes to lower per-part costs.

- Ideal for High-Volume Production: Perfect for running thousands or millions of parts with high efficiency and minimal errors.

Swiss machining is a powerful solution for precision manufacturing, but it’s important to evaluate whether it’s the right choice for your project based on factors like production volume, part complexity, and budget.

When to Consider “Lights-Out” Swiss Machining

One of the exciting capabilities of Swiss machining is the ability to run lights-out machining. This refers to the ability to operate machines automatically during off-hours, allowing manufacturers to increase productivity by running machines overnight or during weekends without the need for operators.

This approach can significantly increase production capacity while minimizing labor costs. However, it’s important to ensure proper safety checks, monitoring systems, and contingency plans are in place when implementing lights-out machining. Without the presence of operators, equipment needs to be thoroughly checked to ensure safe and uninterrupted operation.

Read The Ultimate Guide to Lights-Out Machining to become an expert!

Camco Precision: Mastering the Art of Swiss Machining

At Camco Precision Machining, we’ve perfected the science of Swiss machining over years of dedicated experience. From programming to tooling setup and high-precision machining, we’ve fine-tuned every aspect of the Swiss machining process to meet the most demanding standards in industries like aerospace, medical devices, and automotive.

Our experts leverage the latest Swiss machining technologies to ensure optimal efficiency, quality, and cost savings on every project. Whether you’re looking to streamline your production processes or explore lights-out machining capabilities, we have the expertise to optimize your operations and deliver the best results, every time.

Contact Us to Learn More About A Swiss Machining Quote

At Camco Precision Machining, we specialize in Swiss machining and other high-precision manufacturing techniques. Our team can help you determine if Swiss machining is the best option for your project, ensuring that you get the best results at the most cost-effective prices.

Contact us today to learn more about our services and how we can assist you with your next project. Request your Swiss machining quote today!