Twin Spindle Turning

Multi-Spindle Machining

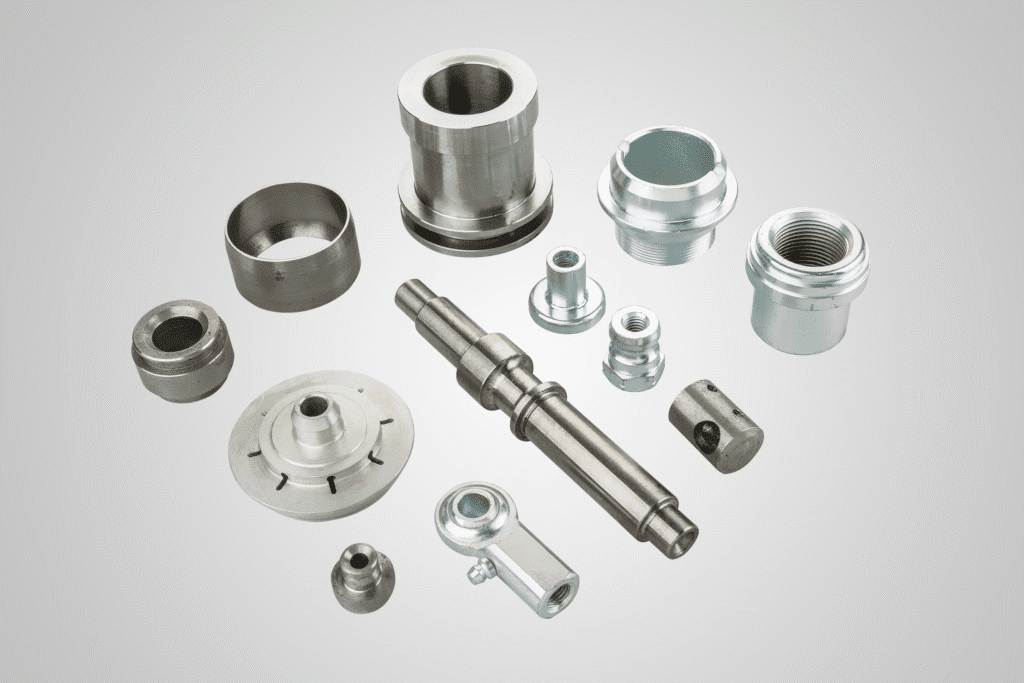

At Camco Precision Machining, our twin multi-spindle machining capabilities offer a significant advantage in high-volume production. Using a main and sub spindle, we perform multiple operations simultaneously, reducing the need for multiple setups and significantly improving machining efficiency. This not only accelerates production timelines but also ensures consistent, high-quality results across large batches. Our advanced twin-spindle turning technology is ideal for producing complex, precision parts with tight tolerances, making it the perfect solution for industries such as aerospace, automotive, and medical manufacturing.

What is Multi-Spindle Machining?

Twin-spindle turning utilizes both a main spindle and a sub spindle to complete operations in a single setup. This approach eliminates part transfers between machines, streamlining the production process and reducing cycle times. By consolidating operations, we can produce parts faster, with greater precision and fewer opportunities for error.

- Reduced Setup Times: By utilizing two spindles, we can complete multiple operations at once, significantly reducing the time spent on machine adjustments and setup.

- Cost Savings: The reduction in setup times and the ability to perform multiple operations in a single cycle leads to low cost machining services for our customers, making twin-spindle turning a highly cost-effective solution for high-volume production.

- Less Labor: With fewer setups and less manual handling, we reduce labor costs, further enhancing the value we offer to customers with multi-spindle machining.

- High Precision: Despite the increased efficiency using multi-spindle machining, we maintain tight tolerances and consistent quality across all parts produced, ensuring the highest standards in every batch.

As a bulk production machine shop, our twin-spindle turning services are perfect for industries that require high-volume, high-precision parts, such as:

- Aerospace

- Automotive

- Medical Devices

- Electronics

- Hydraulics

- And more

- Efficient Production: Our twin-spindle turning machines maximize throughput while minimizing downtime.

- High-Quality Parts: Utilizing multi-spindle machining, we maintain tight tolerances and deliver precision parts every time.

- Cost-Effective: With reduced setup times and fewer labor requirements, we pass the savings on to you.

Request A Quote Today

If you are looking for efficient, high-precision parts for high-volume production, twin-spindle turning at Camco Precision Machining is the solution. Contact us today to see how we can provide low cost machining services for your next project and become your multi-spindle machining supplier. Camco – Swiss machining and screw machining experts!

Industries Served

Precision shafts, Bushings, Small housings, Spacers, Retaining rings and more.

Pinion gears, Spur gears, Gear blanks for transmissions, Bevel gears, Worm gears and more.

Hydraulic valve bodies, Hydraulic pistons, Connectors, O-ring grooves, Flow restrictors and more.

Surgical instruments, Dental implant components, Robotic arm joints, Guide pins, Needle holders and more.

Aircraft fasteners, Brackets, Actuator components, Precision bushings, Aerospace gear blanks and more.

Fuel injectors, Valve bodies, Transmission parts, Brake components, Suspension bushings and more.

Connectors, Mounting brackets, Heat sinks, PCB components, Electrical terminals and more.

Trigger components, Magazine parts, Barrel bushings, Firing pins, Gun receiver components and more.

Valve seats, Pump components, Seals and gaskets, Nozzles, Couplings and more.

Threaded inserts, Heat-set inserts, Retaining rings, Standoffs, Bushings and more.

Valve components, Pressure seals, Pump shafts, Manifold parts, Couplings and more.

Air cylinders, Pressure regulators, Pneumatic valves, Piston rods, Air fittings

Ask a Question

Camco Precision Machining

4701 Haag Drive

Union Grove, WI 53182

262-878-4700

Local to Wisconsin and Chicago, Shipping Quality Machined Parts Nationwide Since 1981.