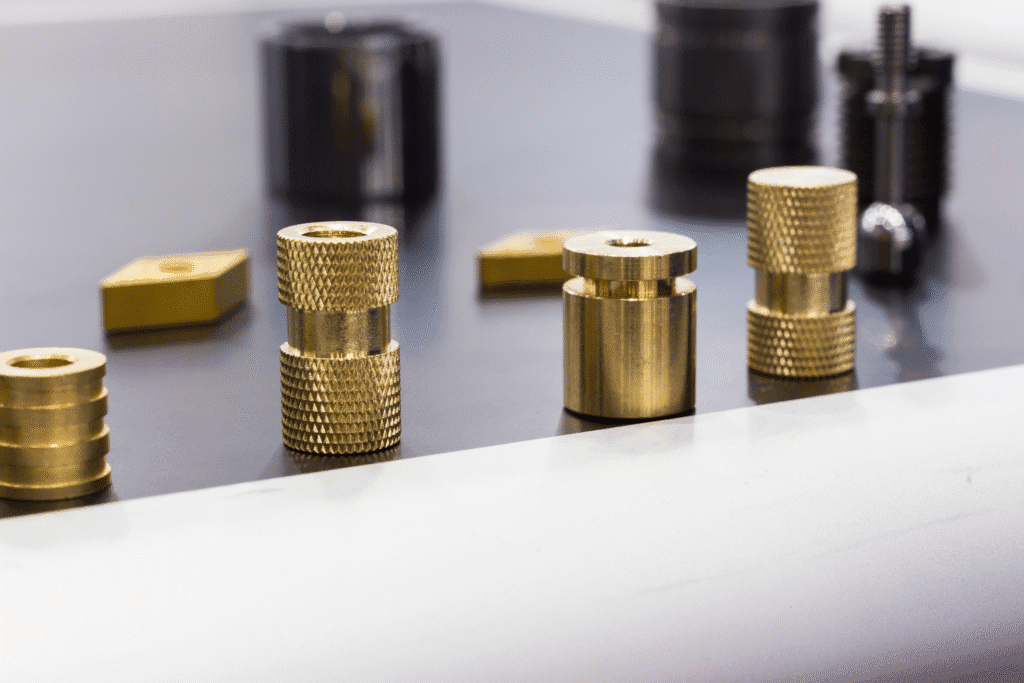

CNC Machined Injection Molding Metal Inserts

CNC Machined Inserts for Plastic Injection Molding

At Camco Precision Machining, we specialize in providing high-quality CNC machined inserts for plastic injection molding. With decades of experience in precision machining, we have developed the expertise to produce custom inserts that meet the stringent requirements of plastic molding applications. Using advanced CNC Swiss machining, CNC turning, and milling technologies, we offer high-precision parts designed for long-lasting performance and reliable fit in plastic injection molding systems.

CNC machined inserts are essential components used in plastic injection molding to enhance the strength, durability, and functionality of molded plastic parts. At Camco Precision Machining, we provide custom inserts that are precisely designed to accommodate a variety of molding applications. Our decades of experience allow us to produce inserts that meet the high standards required for each project.

We produce the following types of inserts for plastic injection molding:

- Injection Molding Threaded Inserts: Brass, stainless steel, and aluminum threaded inserts that provide secure, long-lasting threads in molded plastic components.

- Injection Molding Heat Inserts: As a heat inserts machining supplier, we produce components Ideal for applications where reinforced durability and heat resistance are needed, typically used in automotive and industrial components.

- Non-threaded Inserts: Rivets, expansion inserts, and other components for securing plastic parts without the need for threading.

- Custom Inserts: Tailored inserts that meet specific geometric or performance requirements for plastic molding applications.

High-Volume Production of Metal Inserts for Injection Molding

With our advanced CNC machining capabilities, we are well-equipped to handle high-volume production of CNC machined inserts for plastic injection molding. Our Swiss machines and multi-spindle lathes allow us to efficiently produce large quantities of precision inserts while maintaining high-quality standards. Whether you require smaller batch orders for specialized applications or need millions of inserts for large-scale production runs, we can meet your needs with speed and accuracy, ensuring consistent quality and competitive pricing.

As a machining supplier for injection molding metal inserts, we work with a broad range of materials that ensure optimal performance in plastic injection molding applications. Our material selection is based on the specific needs of each project to provide the best possible performance for long-lasting molded parts. Some of the materials we use include:

- Brass: Ideal for threaded inserts and heat inserts, offering corrosion resistance and excellent machinability.

- Stainless Steel: Strong and corrosion-resistant, used for high-performance inserts in high-temperature environments.

- Aluminum: Lightweight and durable, commonly used for non-threaded inserts and heat inserts where weight reduction is critical.

- Steel Alloys: Used for inserts that require strength and resilience for heavy-duty applications.

- Plastics: Used for custom inserts in non-metal applications, providing corrosion resistance and lightweight properties.

As a supplier of injection molding inserts, we understand that precision is key when manufacturing CNC machined inserts for plastic injection molding. Our team ensures tight tolerances to guarantee proper fitment and reliable performance. Typical tolerances we achieve include:

- Dimensional tolerances as tight as ±0.0001 inches.

- Surface finishes that meet RA (Roughness Average) requirements as low as 32 microinches.

- Thread tolerances for precision inserts used in threaded plastic parts.

We apply rigorous quality control procedures throughout the manufacturing process to ensure that each part meets OEM specifications and performs to the highest standards, whether for bulk production runs or specialized applications.

- Decades of Expertise: With decades of experience in CNC machining, we have developed deep expertise in producing CNC machined inserts that meet the high standards of plastic injection molding. Our knowledge allows us to offer competitive pricing while maintaining precision and reliability in all of our products.

- Advanced CNC Technology: Our CNC Swiss machines, multi-spindle lathes, CNC turning, and milling machines allow us to produce complex inserts for plastic molding with precision and efficiency.

- Material Versatility: We are experts in machining a wide variety of materials, including brass, stainless steel, aluminum, and steel alloys, ensuring long-lasting performance for plastic injection molding systems.

- Quality Assurance: We maintain strict quality control standards, ensuring that every insert is produced to OEM specifications and meets high-performance requirements.

- On-Time Delivery: We understand the importance of timely delivery in the manufacturing process and are committed to providing fast turnaround times while maintaining high quality.

Request a Quote for CNC Machined Inserts for Plastic Injection Molding

If you are looking for precision CNC machined inserts for plastic injection molding, whether for threaded inserts, heat inserts, or custom solutions, contact us today for a competitive quote. Let us help you meet the demanding standards of the plastic molding industry with reliable, high-performance inserts, ideal for high-volume production. Partner with Camco as your molding inserts machining supplier today!

Machining Capabilities

High-precision parts using advanced CNC Swiss machines.

Orders up to 1,000,000+ pieces efficiently produced.

Continuous, automated production from metal bar stock.

Multi-spindle lathes with live tooling for complex parts.

Enhanced efficiency and cost savings for high-volume runs.

Versatile machining for complex shapes and features.

Connectors, Mounting brackets, Heat sinks, PCB components, Electrical terminals and more.

Trigger components, Magazine parts, Barrel bushings, Firing pins, Gun receiver components and more.

Valve seats, Pump components, Seals and gaskets, Nozzles, Couplings and more.

Threaded inserts, Heat-set inserts, Retaining rings, Standoffs, Bushings and more.

Valve components, Pressure seals, Pump shafts, Manifold parts, Couplings and more.

Air cylinders, Pressure regulators, Pneumatic valves, Piston rods, Air fittings

Ask a Question

Camco Precision Machining

4701 Haag Drive

Union Grove, WI 53182

262-878-4700

Local to Wisconsin and Chicago, Shipping Quality Machined Parts Nationwide Since 1981.